Frame building

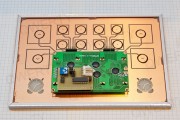

The touch panel PCB is pretty ugly to be a visible interface itself. I made aluminium frame that has two basic functions – aesthetic element and an aid to hold all layers firmly closely together. There cannot be any gap between layers otherwise the capacitive touch sensing is degraded.

It is quite impossible here to buy aluminium profile I wanted (reasonable amount for reasonable price) – U profile, 6 mm x 6 mm x 6 mm, so I bought E profile and tuned it. Resulting profile is 6 mm x 8 mm x 6 mm – two millimeters higher then planned. I am considering to hollow out the wooden shelf a little more to imbed the panel couple of millimeters deeper…

Warning: If you are not skilled in metalworking, don’t try this at home.

Page 1 – Introduction

Page 2 – Controller board

Page 3 – User interface

Page 4 – User interface, part 2

Page 5 – The case

Page 6 – Frame building

Page 7 – Case modification

Page 8 – Shelf installation

Page 9 – Hello World! video

Page 10 – Observations and conclusion

Recent Comments